| |

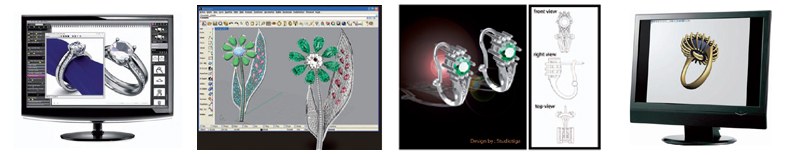

No doubt you have come across the CAD/CAM

acronyms many times in the past few years; the

technological phenomenon that may eventually put

jewellery manufacturing in the layman’s hands. This is

a typical sales pitch presented by CAD/CAM vendors

and may not accurately represent any of the good, or

bad, decisions of investing in this exciting new

development.

CAD stands for computer aided design, while

CAM is an abbreviation for computer aided/assisted

manufacturing. You may have discussed these

technology options with your staff, your bench jewellers

or your accountant, and heard some good reasons why

NOT to jump in. The prohibitive cost, concerns about

training and then the loss of those trained staff, the fear

of industrial mechanisation of an artisan trade, and of

course ignorance of the technology itself.

Before you take the plunge into what can be a

very expensive or foolish investment, jewellers should

consider a number of questions. What is CAD? Is it for

you? Is it for your business? Is it for your staff? Does

your business model support it? Is it only for

manufacturing? Is it for design? Is it for sales? Is your

investment secure? Which CAD should you get, which

CAM? |

|

Design benefits

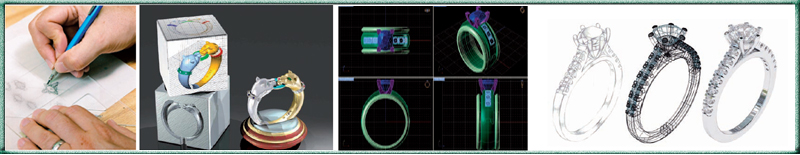

In its most basic form, CAD is for design only –

design with the happy side effect that the design can be

produced by means of various CAM methods into a

piece of actual jewellery – a carbon copy of the drawing

on the screen – and herein lies its greatest benefit and

downfall. There is little loss in translation between the design presented to the client and the final product;

what you see is what you get. Effectively you reduce the

time, errors and money spent in the ‘best-guess’ business

of converting a pencil sketch into a piece of jewellery.

Reading a client’s mind is never an easy business.

Assuming they can read yours, or interpret your sketches

is an even bigger problem.

The design down side is a rather large one. What

you see is what you get. So, if you design a bad piece,

mechanically speaking you will get a bad piece. This is

no different from asking a jeweller to make a bad design

– typically, however, a jeweller will secretly make

corrections for sales people’s awry sketches and bad

design principals. CAD is smart, but also dumb. The

oldest computing adage applies: GIGO – garbage in,

garbage out.

A second, and less known, benefit of CAD for

design is the ability it gives a business to hold an infinite

array of virtual inventory. Each piece has an exact

manufacturing cost, material and stone weight correctly

assigned to it. |

|

The idea of virtual inventory goes beyond the

domain of online vendors and into the realm of the sales

floor. Marrying the actual stock with a design inventory

allows you to utilise the parametric nature of CAD to

hold a limitless array of design iterations. Present a

client with an actual piece to examine and hold a dozen

design variations in a booklet, all produced and rendered

with no outlay other than the time spent designing using

CAD. A virtual stock hold worth millions, for the price

of a single CAD installation.

This stock hold can be also used as a very

effective advertising medium. The lines between this

type of advertising and the crossover to virtual inventory

have started to blend. Some companies can pre-sell an

entire range before ever having had a single model

produced.

This parametric nature of CAD also helps reduce

redesign time significantly; allowing your designer and

jeweller to produce far more in less time, with the added

benefit that ‘no go’ designs for one client may very well

be useful for another, or simply to add to your virtual

inventory. |

|

CAD in sales

CAD in sales has been limited to large scale

manufacturing plants until now, yet it has been a very effective one. The advent of new smarter and slimmer

technology allows the sales team to take devices like

iPads or TabletPCs onto the sales floor. Younger (and

increasingly older) buyers are aware of CAD because

of the massive surge in online vendors who use it to

finalise designs prior to manufacturing.

Almost everyone nowadays has some form of

smartphone or mobile computing device, so bringing

technology onto the sales floor is no longer taboo. A

quick tally finds five CAD drawing applications for

iPhone/iPad and a dozen or so ‘CAD viewers’ (that will

allow you to view CAD files but not create them) for

industries from cabinet making to house design and

automotive design, and almost every new luxury item

you have bought, from the car to the yacht has had its

roots in CAD or CAM.

Jewellery manufacturing or sales cannot escape

this logical evolution. Programmes like Gemvision’s

CounterSketch can soon be brought onto the sales floor

on a tablet-sized PC and the process of designing an

entire ring can be done by the client, with no knowledge

of CAD required. Drag a slider here, make the ring

bigger, drag a slider there, make the centre stone

bigger, click a button and swap the metal from 9K to

18K.

This will without a doubt change the way we sell

custom-made jewellery. CAD will free sales people from having to consult a manufacturing jeweller to find

out if the item is practical to produce and what the item

will cost. In fact, the sale is actually made by the client.

If the client doesn’t like the price they are free to drag

the shank thinner themselves, sparing a few dollars in

weight but enabling them to see the big impact it has on

the overall design. The piece is produced, set and

finished and delivered back to you in two weeks. No

headaches. |

|

The downside to this sales application of CAD is

that if there are no local servicers at present, then it must be serviced abroad and your hard earned money leaves

the country. Hopefully this will change and more users

will be able to be serviced locally in future.

Manufacturing CAD

This subject is a massive one to tackle and will not

be resolved fully for at least another 10 years – by

which time all manufacturers will be using this technology. The biggest factor to consider when

implementing CAD for manufacturing in your

workshop is surprisingly, the human factor. Consider

that most older bench jewellers who saw the quartz

movement kill watchmaking will view any new

technology on the bench with a wary eye.

Allaying this fear is the primary goal or your

entire installation will suffer – because it is exactly these

jewellers who are required to make the system work

properly, make sure no one inputs bad design principles. |

|

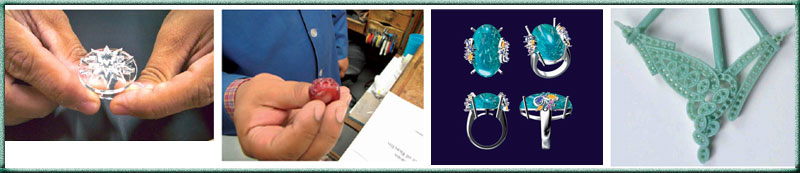

The ‘GIGO’ effect

CAD is a programme– only a programme – andas such its output is dependent on the jeweller or

designer’s input. Give two jewellers the same saw

frame and you will get two different results. And herein

lies CAD’s biggest advantage and also its biggest downfall. People with no natural or learnt ability on the

bench are able to use CAD to produce jewellery – even

fantastically complicated pieces – but the question

remains, will that piece be practical or durable.

Unfortunately the answer, most of the time, is no.

The majority of people who are actively learning

CAD now have no experience with what constitutes a

viable piece of jewellery. This has resulted in the

proliferation of cheap, light and poorly conceived

models hitting the retail market. Jewellery that is so

weak, that even whispering the word ultrasonic

anywhere near it makes three stones fall out.

There is currently a recruitment drive by larger

manufacturers to employ classically trained bench jewellers to write engineering standards for their CAD

departments to overcome this problem.

The simple and undeniable fact is that bench

jewellers actually make the best CAD artists and they

tend to ramp up the learning curve much faster. Jewellers

need to invest in their staff because CAD will not

replace them, it will merely augment what they do. The

marriage of CAD to a good bench jeweller is a remarkable

thing to witness, allowing that jeweller to produce more

- better and faster than he could have ever imagined.

If you do not have access to a manufacturing

jeweller it may be worth your while to invest in a short

course on jewellery manufacturing to give you a few

basic ideas about casting and setting requirements –

this will pay off far more than repetitive CAD lessons

from different providers.

Simply put, CAD is a reality in the here and now

– not in some distant future. It has arrived and jewellers

need to know how to make it work for them, to earn

income. |

|

| |

|

|