Results

Long Term UV Exposure

Of particular interest to

this study, however, is the reaction of the stones after

long-term exposure to intense UV light. The Beryllium-Treated

samples from Madagascar reacted differently to all other

samples, excluding unheated ones (See Table A1). Significant

changes in the color were seen in samples heated with Beryllium,

and a shift towards more yellow or orange was observed (as

shown in the Table A1). A color change from near colorless

to yellow was also observed in untreated sapphires of Sri

Lankan origin (Table A1). This unheated group of sapphires

is known to contain specific color centers (Lit. 16). In

Beryllium-Treated gemstones with an orange body color before

the UV experiments, the color shift is more difficult to

see. The color change towards more yellow or orange could

be reversed when exposed to a gas flame for a short time,

and within two days when exposed to a 100 watt halogen lamp

at slightly elevated temperatures. A set of white sapphires,

which did not change color during the Berylllium-treatment

process developed a thin layer of yellow color during the

long term UV exposure (shown in Fig. A4). This observation

was also made on Beryllium-Treated blue sapphires (Fig.

A4) which have been exposed to UV. The blue samples developed

orange edges, while the body color of the sapphires remained

unchanged. The color induced by UV treatment could be reversed

by short application of heat to all the samples, beside

one exception.

Scanning Electron

Microscope Analysis (SEM)

Sampling of colored sapphires

heated by the new treatment in Chantaburi included the study

of faceted Beryllium-Treated gemstones (Materials group

f.). These gemstones were already faceted in briolette and

princess-cut style sapphires prior to heat treatment. By

sorting the lots after heat treatment, a set of non-sapphire

materials were detected (Fig. A8). The colored samples showed

a thin film of interference color at the surface, and were

indented by craters due to contact with other minerals in

the same heating process. These craters were also found

indented on the surface of the sapphires (Fig. A13). The

materials were identified as consistent with glass-aggregates,

zircon and chrysoberyl (Table A2).

Furthermore, clusters of sapphires,

sintered together by a whitish matrix, were detected. Only

an extremely small portion of the gemstones showed this

phenomena and it was clear that these were accidental circumstances.

In order to analyze the surfaces

of these materials, and to search for potential trace elements

used in the process, the materials were studied with a Scanning

Electron Microscope (Philips XL 30 ESEM) in February 2002

at the University of Basel's Central Laboratory for Microscopy

(ZMB) by Chief Technician M. Duggelin and D. Mathys. Five

samples were selected (including minerals with an interference

film (zircon and chrysoberyl), and sapphire clusters |

|

Results

SEM

Analyses of

zircon and chrysoberyl did not reveal any further

information on chemicals present, other than expected

from their chemical compositions and attention was

placed on the sapphire clusters and the white matrix

around the sapphire materials. Cracks and intended

craters were investigated, and a series of newly

formed crystallizes were detected in these cracks

(Fig. A15-A17), mostly composed of Zr-oxide, plus

additional element Silicon (Si), Aluminium (Al)

, Magnesium (Mg), Calcium (Ca) and Fluorine (F).

Beryllium can not be measured with SEM, and no indications

for Chromium (Cr), Titanium (Ti), or Iron (Fe),

were found on the surfaces of the enhanced gemstones.

Most of the detected elements can be explained as

originating from decomposed minerals present in

the runs (Silicon (Si) and Zirconium (Zr) from zircon,

Aluminium (Al) from corundum, or chrysoberyl), yet

the source of Fluorine (F) is unclear. Melting on

the surface of these minerals is very visible, as

different craters are present on the surface of

the former faceted materials (Fig. A8) and also

by the craters produced at the surface of the sapphires

(Fig. A13, A14). They were formed when they came

into contact with other chemical compositions present

in other minerals - of the same shape, cutting style

and size - in the heating run. Chrysoberyl is a

potential source for Beryllium. Its role in the

heat treatment process has been confimed (See later

publications Lit. 23-33).

|

|

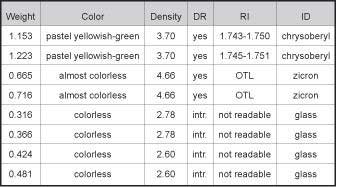

Table

A2 :Selected representative ID Data on

the identified minerals accompanying the sapphires

heat-treated in the presence of Beryllium. Samples

cut in half and polished. |

|

|

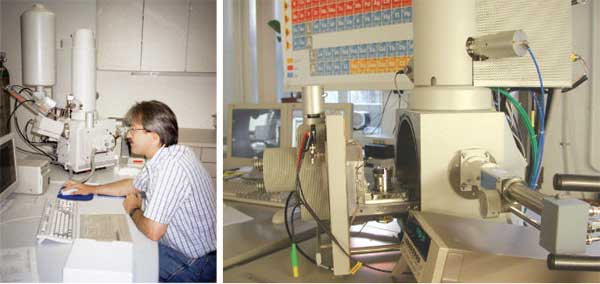

Fig. A7

An example of a SEM-EDS recently used for research

is shown from the University of Fribourg, Earth Science

Department, Switzerland. On the left: Prof.B. Grobety

operating the SEM (FEI XL 30 Sirion FEG). To the right

details of the SEM: An opened sample chambre, surrounded

by a variety of detectors, such as Secondary Electron

Detector (SE), Backscattered Electron Detecor (BSE)

and an X-Ray Detector (EDS) with a Polymer Window

(S-UTW), for microchemical analysis. |

|

Fig.

A8 A set of non-sapphire materials sorted

after heat treatment experiments. In December 2001,

heat treatment was carried out with the new method

in Chantaburi (Thailand) on a lot of briolette sapphires

and then inspected by GRS at the source. First row:

Method no-sapphire material transformed to whitish

glass-aggregates. Second row: Zircon miterals (radioactive).

Third row: Chrysoberyl minerals. (Note: Creters on

the surface of the zircon and chrysoberyl crystals

due to contact with other minerals in the heat treament

process and partial melting of the surface, See arrows).

Overgrowing layers of thin films with interference

color were found on zircon and Chrysoberyl samples,

indicating some chemical reactions on their surfaces.

Samples collection GRS. |

|