|

Prestigious Innovations Prize awarded at Inhorgenta

Europe

Each

year at Inhorgenta Europe, the Innovations Prize is awarded for outstanding.,

future-oriented jewellery design. The winners of the prize awarded

at the recent Inhorgenta Europe 2004 were Claudia Hoppe from Germany,

Norika Matsumoto from |

|

| |

England,

Yvonne Raab from Germany and Karin Wagner from Switzerland.

In the five years since the award was launched, it has become

one of the most prestiqious prizes in the design sector. Inhorgenta

Europe, with 300 exhibitors alone in the designer jewellery

section, has risen to become the biggest platform for designer

jewellery worldwide. |

|

|

|

|

| |

For

the Inhorgenta Europe 2004 Innovations Prize, 151 designers

submitted nearly 450 pieces. The creations came from 10

countries -- Belgium, Germany, France, Great Britain, Italy,

Japan, Poland, Switzerland, Spain and Taiwan. From these

the four winners were chosen by an international jury of

recognised experts, comprising Angela Oelckers, editor-in-chief

of AMICA (Hamburg), Monica Gaspar Mallol, curator of contemporary

jewellery at the Museum of Applied Arts (Barcelona), Prof.

Susan Cross, lecturer at the Edinburgh College of Art, Jytte

Kloeve, a designer from Lyng-by (Denmark) and Isabella Hund,

a gallery owner from Munish.

The

prize-winning pieces were displayed in a special exhibition

at Innorgenta Europe, on 'Desingers' Avenue ' where rhe

awards ceremony also took place. the winning designers gave

some insight into their designs and influences.

"My jewellery is an invitation

to you to decorate yourself, or people you like, in a way

that pleases you. Some of my pieces - - with their colourfulness

and provocative combination of stainless steel and plastic

- - are just asking the wearer to expiriment with them.

Individual components can be switched around, so that the

wearer can put together their own very individual items

of jewellery. Others are more restrained, yet their classic

forms and traditional materials contain a secret that, depending

on taste, can be found out by thinkingabout it or trying

it out. Enjoy, "said, Claudia Hoppe, one of the four

winning designers of the Innovations Prize. |

|

|

|

|

| |

"My

collection focuses on the transformation of shapes. Shapes communicate

different meanings depending on how they are manipulated by altering

their scale, volume or construction . I intend to investigate ther

design potential of these alternatives and develop them into jewellery

pieces. The basic shape I shall use is anonymous, abstract and simple

yet gives a familiar impression to audience. In this collection,

I develop it in two dimentions, using line and volume. As for materials,

silver is employed as the main one. The neutrality of its colour

and quality is a very interesting feature for me. These aspects

can encourage me to reveal clear impressions from each form. In

order to emphasise them I focus on three colours, silver, black

and gold, " explained award winner, Noriko Matsumoto. |

|

| |

|

|

| |

"The

inspiration comes from the mountains, my home,

from memories of childwood, from the many beautiful

colours of nature. I love the combination of

romance, tradition and contemporary design,

mixed with a pinch of humour. To sum up, my

jewellery creations are characterised by three

criteria: romatic playfulness combined with

'coolness', a mixture of tradition, history

and fashion design, and a combination of craft,

art and design," said award winner, Karin

Wagner. |

|

www.inhorgenta.com Images

copyright: Messe Munchen GmbH/Photos: Loske

(le)

|

|

Large

diamonds made from gas are the hardest yet

Producing

a material that is harder than natural diamond has

been a goal of materials science for decades. Now

a group headed by scientists at the Carnegic Institution's

Geophysical Laboratory in Washington, D.C., has produced

gem-sized diamonds that are harder than any other

crystals . Futher, the reserchers grew these diamonds

directly from a gas mixture at a rate that is up to

100 times faster than other methods used to date.

"These

are real diamonds made of carbon and identical in

structure to those formed in nature and by high pressure

and temperature methods, " siad Chih-shiue Yan,

lead author of the study published in the February

20, online Physica Status Solidi. "We believe

these results are major breakthroughs in our field.

Not only were the diamonds so hard that they broke

the measuring equipment, we were able to grow gem-sized

crystals in about a day."

The reserches

grew the crystals using a special high-growth rate

chemical vapor deposition (CVD) process that they

developed. They then subjected the crystals to high-pressure,

high-temperature treatment to further harden the material.

In the CVD process, hydrogen gas and methane are bombarded

with charged particles, or plasma, in a chamber. The

plasma prompts a complex chemical reaction that results

in a "carbon rain" that falls on a seed

crystal in the chamber. Once on the seed, the carbon

atoms arrange themselves in the same crystalline structure

as the seed. In thiscase, the seed was a type 1b synthelic

diamond plate. They have grown single crystals of

diamonds up to 10 millimeters across and up to 4.5

millimeters in thickness by this method.

|

|

|

|

| |

|

|

| |

The

crystals produced by CVD are very tough, "We noticed this

when we tried to polish them into brilliantcuts, "said Yan.

"They were much harder to polish than conventional diamond

crystals produced at high pressure and high temperature."

The researchers then subjected the tough CVD crystals to high-temperature

and high-pressures between 50,000 and 70,000 times atmospheric

pressure (5-7 GPa) for ten minutes. This final process resulted

in the ultrahard material, which was at least 50% harder than

the conventional diamonds as shown by direct measurements carried

out in collaboration with scientists at Los Alamos National Laboratory.

"Making

diamonds has not been the primary goal of our research,"remarked

Russell Hemley of Carnegic. "our group is interested in the

behavior of materials at extreme pressures and temperatures. We

need large, perfect diamond crystals to create new classes of

high-pressure devices for our research and decided to explore

whether we could make these crystals by CVD processes. We found

that we could, and at a very high growth rate. This has opened

up an entirely new way of producing diamond crystals for a variety

of applications, such as the next generation diamonds-based electronic

devices and cutting tools. Our new finding that the diamonds can

be supertough and/or superhard was a surprise and will greatly

benefit many of these applications."

This

research was supported by the National Science Foundation, the

U.S. Depertment of Energy, the National Nuclear Security Agency,

through the Carnegie/DOE Alliances Center, CDAC, and the W.M.

Keck Foundation . It was conducted in collaboration with researchers

at the Phoenix Crystal Corporation and Los Alamos National Laboratory.

The Carnegie Institution of Washington (www.CarnegieInstitution.org)

has been a pioneering force in basic scientific research since

1902. It is a private, nonprofit originization with six research

depertments in the U.S. : Plant Biology and Global Ecology in

Standard, CA; The Observatories in Pasadena, CA, and Chile; Embryology,

in Baltimore, MD; and the Department of Terrestrial Magnetism

and the Geophysical Laboratory in Washington, DC.

http://carnegienstitution.org

|

|

|

Lead-glass Impregnated

Ruby GAAJ Lab. Alert - - Research Laboratory, Gemmological Association

of All Japan

We encountered

a ruby which showed flash effect from fissures and fractures. Our

analysis revealed that the stone was impregnated with lead-bases

glass. This report describes details of the material. |

|

| |

Treating

diamonds by impregnating cleavages or fractures with highly

refractive glass to improve the clarity (transparency) has

been commonly known. This type of treatment appeared on the

market around 1987 and has been called glass "filling."

It is also called "Koss" treatment or "Yefuda"

treatment, named after the treaters. Cleavages and fractures

in these treated diamonds show unique rainbow-coloured light

called the flash effect. This optical effect is caused by

the difference in dispersion between diamond and the impregnating

material, but refractive indices of the two materials should

be almost overlapping. In other words, a host gemstone and

an impregnating material should have very close refractive

indices and different dispersions to show the flash effect. |

|

|

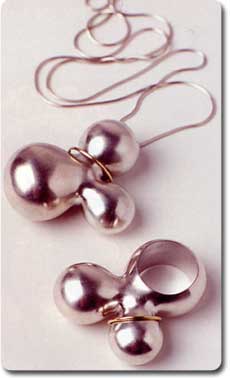

Photo

1:A 13.220 ct ruby impregnated with lead-based glass |

Photo-2: Flash effect is seen from fissures and fractures.

Photo-3: A radiograph. White streaks in high contrast correspond

to the distribution of fractures. |

This

flash effect recently started being seen in some faceted ruby.

Shown in the Photo-1 is a 13.220 ct ruby, whose internal features,

spectral analysis and other tests indicated that the stone

has been heated and may have its origin in regional metamorphic

rock such as found in African corundum fields. This ruby was

faceted but many cracks reaching to the surface were observed

inside the stone. From these cracks, an odd blue to purple

light effect (flash effect), which was different from ordinal

interference of thin film, was observed (Photo-2). Residues

from heating processes may often be seen in fractures and

cavities in ruby, but they never produce a lower refractive

indices than ruby; thus, they never produce a flash effect.

The flash effect seen in ruby indicates that the stone is

impregnated with substances whose refractive indices overlap

that of ruby. To identify the substance and to confirm the

degree of the impregnation, we performed an X-ray test and

X-ray fluorescence analysis. The radiograph is shown in the

Photo-3. Many white streaks in high constrast correspond to

distributed fractures developed in ruby. The uniform white

part in the radiograph indicates existence of elements which

have larger atomic mass than the host ruby (Al203).

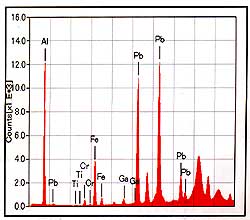

Figure-1

shows the results of measurements by X-ray fluorescence analysis

of the fractures reaching to the surface. In the results,

detection of Pb(lead) stands out beside the main chemical

element of Ruby, AI, and common trace elements. The existence

of light elements such as boron cannot be denied at the present

stage, because the X-ray fluorescence analysis cannot detect

those light chemical elements. |

From

the observation and analysis described above, the newly appearing

ruby showing the flash effect must be highly fissured or fractured

ruby from Africa or other sources, which have been impregnated

with lead-based glass having a similar refractive index, for

the purpose of clarity improvement.

GAAJ

REsearch Laboratory. Copyright 2004 Zenhokyo Co.,Ltd. All

rights reserved. Reproduced by permission.

www.gaaj-zenhokyo.co.jp |

|

|

| |

|

Figure-1: Results of X-ray

fluorescence analysis on fractures.

|

The

Israel diamond Musuem opens rare gemstones & minerals

exhibition

The Harry Oppenheimer

Diamind Musuem in Ramat Gan, has opened a unigue exhibition

of gemstones and minerals, |

|

|

containing

500 rate items, gathered from 55 countries around the

world. The private collection of Ben-Zion and Sarah

Harel, accumulated over a period of 30 years, this unique

treasure will form part of the permanent collection

of the museum. Among

the unique pieces on display are a prehistoric insect,

resembling a mosquito, trapped in amber over 20 million

years ago. Also featured is two billion year-old crystal

from Nambia, containing a droplet of water, which moves

freely within the stone. Another highlight is the largest

ruby in the world - - weighing 1908 grams, originating

from Kenya.

Other

exhibits include, a 25 million year-old red emerald

embedded in stone. "Emerald Crystal Twins"

from Northern Afghanistan - a perfectly-formed crystal

that sprouted a second perfect crystal, and a fossillized

tree trunk which grew calcite crystals - an exceedingly

rare combination in nature weighing 5112 grams. |

Emerald

crystal |

|

|

|

Ben-Zion

Harel is an international gemstone dealer, who founded and

headed for more than a decade the israel Emerald Cutters Association.

He was also a founding member of the International Colored

Gemstone Association. Mr Harel, whose family has been actively

trading gemstones between Europe and the Orient since the

19th century, has a deep knowledge and affinity for minerals

and semi-precious stones. he created the collection from pieces

acquired on is many trips around the world.

The

Harry Oppenheimer Diamond Museum, a subsidiary of the Israel

Diamond Institute is located in the Maccabi Building within

the Diamond Exchange complex. It features unique permanent

and changing exhibitions presenting the magical world of diamond,

gemstones and gem-studded jewelry.

|

|

Left

to right : 1) Kunzite crystal 2) Ruby crystal 3) Red beryl

crystal

www.diamonds.org.il/Museum.html

|

|

|

|